If you can dream it

we (probably) can print it.

Multi Color FDM and Resin printing

Welcome to the future of innovation and limitless possibilities – welcome to our 3D Printing Business. In a world where technology is constantly pushing the boundaries of what's possible, 3D printing has emerged as a revolutionary force, changing the way we design, create, and manufacture.

Turning Your Ideas into Reality, Layer by Layer!

Our 3D Printing Business is at the forefront of this exciting transformation, offering a gateway to a universe of creativity and innovation. We bring to you the power to turn your imagination into tangible, three-dimensional objects. From intricate prototypes and functional parts to personalized products and works of art, we make the extraordinary accessible.

Multiple disiplines

With state-of-the-art 3D printing technology and a commitment to quality and precision, we are here to redefine the way you think about manufacturing, prototyping, and customization. Whether you are an entrepreneur seeking to revolutionize your industry, an artist pushing the boundaries of creativity, or an individual looking to bring your unique concepts to life, we are your partner in this exciting journey. Join us as we embark on a voyage to explore the endless horizons of 3D printing, where innovation knows no bounds, and the impossible becomes achievable. Welcome to the world of 3D Printing, where your imagination becomes reality, one layer at a time.

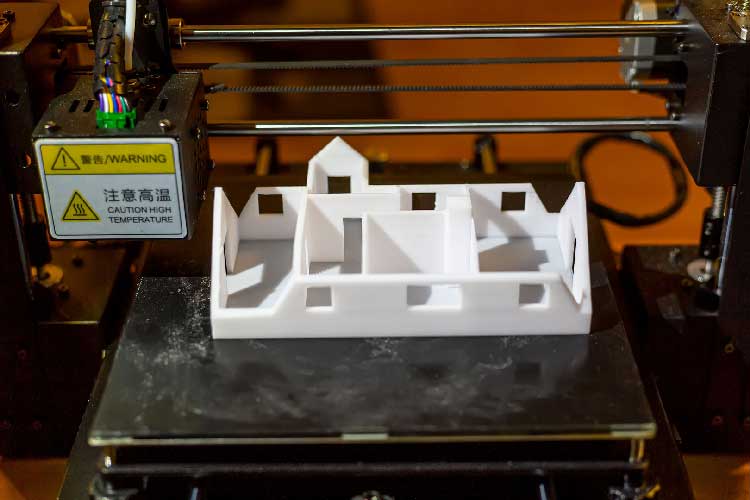

3D Fused Deposition Modeling (FDM

FDM is a widely used 3D printing technology that creates objects layer by layer by extruding thermoplastic filament material through a heated nozzle. The material is deposited onto a build platform, and it solidifies as it cools, forming the final 3D object.

FDM is compatible with various thermoplastics like PLA, ABS, PETG, and more engineering grade materials as Nylon, Carbon Fiber, Poly Carbonate... The choice of material depends on the specific requirements of the printed object.

FDM is versatile and commonly used for rapid prototyping, producing functional parts, and creating low-cost custom components. It is suitable for both engineering and hobbyist applications.

FDM has limitations in terms of surface finish and resolution, making it less suitable for applications that require highly detailed and smooth objects (we refer to Resin printing for smooth high detail prints). We offer post-processing on request, this can be, smooth sanded, base coated ready to paint or completed and airbrushed.

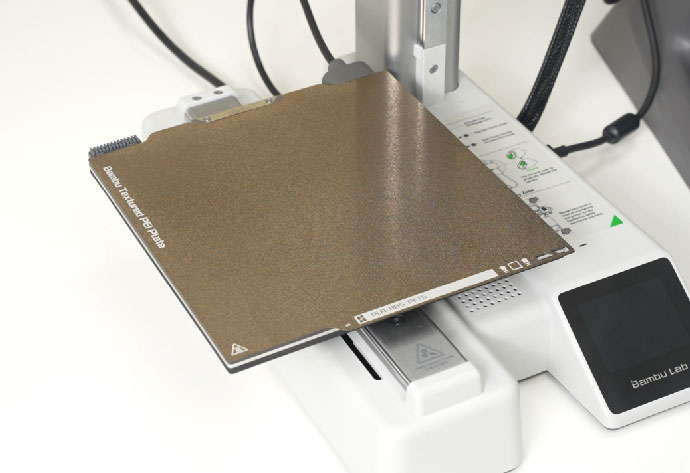

Multi Color FDM prints

Multi-color Fused Deposition Modeling (FDM) 3D prints are created by using a 3D printer that has the capability to deposit multiple filaments of different colors during the printing process. FDM is a commonly used 3D printing technology, and achieving multi-color prints.

We use Bambu Lab printers with AMS system. Be aware that multi color prints requires a lot of purge (waste materials) and can significant increase the production costs. We at NERDS.PH can inform you how to reduce these costs and still achieve exelent results.

NERDS.PH is also HueForge licensed so we can deliver realistic photo prints and stl files ready to print.

Resin Printing (LCD and DLP)

3D resin printing, often referred to as Stereolithography (SLA) or Digital Light Processing (DLP) 3D printing, is an advanced additive manufacturing technology that creates highly detailed and precise three-dimensional objects using liquid photopolymer resins. This technology is particularly renowned for its ability to produce smooth and intricate prints with exceptional resolution, making it a preferred choice for applications that demand precision and aesthetic quality.

Resin printing excels in applications where precision, intricate details, and smooth surface finishes are critical. Some common applications include:

Jewelry: Creating intricate and detailed jewelry pieces.

Dental and medical: Producing dental models, prosthetics, and anatomical models.

Miniatures and figurines: Crafting highly detailed figurines for gaming and collectibles.

Prototyping: Developing precise and functional prototypes for engineering and product design.

We have both LCD and DLP Resin printers with a resolution up to 18 µm. (a human hair is around 80 µm).

Our DLP Resin printer has a smaller build surface and therefore is limited to smaller objects. The recommended field is medical (dental) models and models printed in castable wax for jewelry making.

How can we assist

FDM 3D printing offers a versatile and accessible way to turn digital designs into tangible objects. Whether for rapid prototyping, DIY projects, or custom manufacturing, FDM technology continues to evolve and expand its capabilities, making it a valuable tool for a wide range of applications.

3D resin printing is a valuable technology for creating highly detailed and visually impressive objects, especially in industries where precision and aesthetics are paramount. Its ability to faithfully reproduce intricate designs with a smooth, polished finish has made it a preferred choice for professionals in fields like jewelry design, dentistry, and fine arts.

FAQ on 3D Printing

1. Some 3D printed objects are readily available at our shop (Lazada/Shopee), this is the cheapest solution.

2. You have a file on hand and we print it for you. Costs involved are a small fee for slicing corrections (if needed), filament costs calculated per gram of plastic used, print time fee and post processing fee is requested.

3. We can make your design from drawing to 3D printed model.

4. Color prints can be more expensive due to the fact that more waste material is created. Cost can be reduced by printing multiple models at the same time or use less colors or less complex colored designs.

HueForge is a software suite that makes it possible to convert photo's and graphics to 3D printed objects. For every filament color we measure translucency and we use this to generate mult-color prints that can be used for keychains (logo's), earrings, family pictures cooperate gifts, coasters etc. With HueForge you get unique designs and we have readily available designs in our shop. We are also licensed to sell our files as digital download so you can print them your own.

1. You can send us your files and we can print them, if the files have pre-support then you pay for print time and resin calculated per gram.

2. If we receive files where supports are missing then we will calculate a fee for pre-production.

3. If you see models on line that you would like to be printed then NERDS.PH can go thru to process of buying licences for the model and provide you with the finished product. Yes NERDS.PH will always make sure that the artist who created the model will recieve his/her fair share.

All designs offered by NERDS.PH are licensed and we are allowed to print on demand. Files that are send to us for printing: We will ask you to sign a waiver confirming that you have the rights of the model, have paid the creator or contacted the creator and are allowed to use the file for 3D printing. NERDS.PH cannot be hold responsible for copyright infringements and acts as 3D printing service provider only. Therefore, we will not accept requests of downloading a non-licensed file for printing. We can contact the creator and ask for permission to print the file, of course this will involve costs (license, administration fee).